Medical Shaver Blade

Application domain: for arthroscopy endoscope

Material: Super-high rust-resistant high-hardness stainless steel, ceramics, general stainless steel

Medical Shaver Blade P262

Characteristics

Application domain: for arthroscopy endoscope

Material: Super-high rust-resistant high-hardness stainless steel,

ceramics,

general stainless steel

Products Description

LZQ is an OEM factory for all kinds of shaver blades, such as Endoscopic/Arthroscopic Shaver blade P259, Bone Drill Point P227, Bone Fetcher P165, Drill Bit 096, ect.

We use the material of stainless steel and ceramic.

We are capable to produce any shaver blades according to drawings or samples provided by customer with a favorable cost-performance.

Our SHAVER BLADES & BURS are set apart by:

Very good cutting properties; Long service life and durability; Reusability; No metal abrasion; Well-fitting couplings

The benefits to you:

More convenience for operating personnel; Increased precision for surgical procedures; Savings with consumables; Shorter operation times

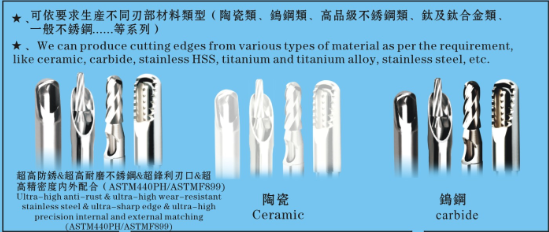

Cutting edge Material Types:

- ultra-high anti-rust high wear-resistant stainless steel(AA)(HRC54°±2°Section)(regular stock)

2. general anti-rust ultra-high wear-resistant stainless steel(A)(HRC64±°2°Section)

- butt welding hard alloy(carbide)(HRA87°~94°)series(customizable)

The inner blade and outer blade are grinded with high speed by 6-axis 5-linkage CNC superhard grinding wheel (CBNC). The edge can be close to the mirror finish, super-sharp (relief angle can be 20 ° ~ 70 ° series), super clean and excellent cutting during surgery.

At present , LZQ is good at producing tools for high-hardness, high wear-resistant andhigh impact-resistant products, like High-temperature alloy, Heat-resisting alloy, Vanadium-titanium alloy of nickel iron, Stainless steel, Cobalt-based nickel alloy, Titanium alloy or other items, made of difficult-processing material, and have done a good job. There are about 300 kinds of material we often use, like the imported ones, HRF10/K15A(for application from super-finish machining to semi-finish machining and for high-hardness processing), MR11(for application from finish machining to semi-rough machining, and the use of hard-processing material ), H10F/PR40(for widely-used and ordinary processing application), VAR201(for high wear-resistant and chipping-resistant application), ASP60A(HSS-Co10), SKH57C(HSS-Co), ASTM440PH…totally about 300 kinds of material.