Surgical bladed wheel

Application domain: orthopedics

Material: Ultra-high anti-rust high-hardness stainless steel,

general rust-proof ultra-high wear-resistant stainless steel,

ceramic

Type

Bone saws, Gums saws

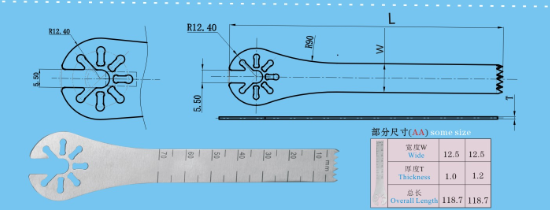

Surgical bladed wheel P250

Characteristics

Application domain: orthopedics

Material: Ultra-high anti-rust high-hardness stainless steel,

general rust-proof ultra-high wear-resistant stainless steel,

ceramic

Type

Bone saws, Gums saws

Products Description

LZQ is an OEM factory for all kinds of dental implant wrenches, such as, Bone Saw P250,Cutting Bur/Bone File P190, Drill Stopper P31, Drill Bit 096, Abutment/Transfer P25, , etc. We can also produce a whole kit of tools for customers’ surgical cases.

We use the material of Ultra high anti-rust and high-hardness stainless steel

We are capable to produce any wrenches according to drawings or samples provided by customer with a favorable cost-performance.

(Ultra-sharp edge&ultra-high wear-resistant&ultra-high rust&high precision)

Material classification:

1. Ultra-high rust-proof & wear-resistant stainless steel (AA)

(HRC54°±2°Section) (regular stock)

2. Conventional standard rust-proof and wear-resistant stainless

steel (A)(HRC52°±2°) series

- Ordinary antirust stainless steel (A) (HRC62°±2°)

If meet the assembly space demand, saw tooth can be customized with different thickness, width, tooth shape, number of teeth, angle, sharpness.

We can customize high-precision-combination molding fixture, brazing fixture, wear-resistant accessories, high-precision parts by (3DX technology) molding superhard and superfine grinding, with ceramic, tungsten steel, stainless steel, titanium alloy, titanium diamond series, according to customers' drawings or samples,

When you make inquiry, referencing to the page footer, please provide samples with best work performance, and specify the detailed requirements, material types, dimensional tolerances, drawings of finished and semi-finished products, equipment used or equipment value (to judge its rigidity and runout, etc), monthly consumed qty, type of original samples and its inadequacies, the workpiece material to be processed by sample and its hardness HRC? ...

Any deficiencies, please do not hesitate to let us know: Is it easy to get passivated? Or tipping? Or something else? Please provide new and old samples--with the best working performance--for us to check and test.